Introduction

In the world of Lean manufacturing and operational excellence, 5S stands as a foundational pillar that drives discipline, efficiency, and workplace clarity. Originating from the Japanese industrial system and widely adopted through the Toyota Production System (TPS), 5S offers a simple yet powerful framework for organizing workspaces and building a culture of continuous improvement.

The methodology—Sort, Set in Order, Shine, Standardize, and Sustain—goes beyond mere cleanliness. It enables organizations to eliminate waste, reduce downtime, enhance safety, and increase employee engagement. When implemented correctly, 5S doesn’t just transform the shop floor—it transforms mindsets.

This blog explores the meaning, practical steps, tools, and benefits of the 5S methodology, guiding you through each phase with clarity and actionable insight. Whether you’re launching a Lean initiative or reinforcing workplace standards, 5S is the perfect starting point for long-term operational success.

1️⃣Seiri (Sort)

Objective: Eliminate clutter and anything that doesn’t belong.

- Tag and remove broken tools, excess materials, or obsolete files.

- Use red-tagging techniques to temporarily relocate unneeded items.

- Free up space, reduce distractions, and improve visibility.

🔍 Ask: Do we really need this item here?

2️⃣ Seiton (Set in Order)

Objective: Organize everything that remains for maximum efficiency.

- Designate a “home” for every tool, material, or document.

- Use shadow boards, labels, and floor markings for quick access.

- Tools should be stored based on frequency of use.

🔍 Ask: Can anyone find what they need within 30 seconds?

3️⃣ Seiso (Shine)

Objective: Clean the work area and identify issues through cleaning.

- Regular cleaning helps detect oil leaks, damage, or misalignment.

- Assign cleaning duties to operators for ownership.

- Make cleaning part of the job, not a separate task.

🔍 Ask: Is this area clean enough to spot abnormalities?

4️⃣ Seiketsu (Standardize)

Objective: Create standards and routines to sustain the first three S’s.

- Develop checklists, SOPs, and visual guides for daily tasks.

- Use audits and visual cues to monitor compliance.

- Involve everyone in defining and maintaining standards.

🔍 Ask: Are our practices consistent across all shifts?

5️⃣ Shitsuke (Sustain)

Objective: Embed 5S into the culture through habits and discipline.

- Reinforce through training, recognition, and leadership example.

- Conduct regular reviews and Kaizen events.

- Build a culture of accountability where 5S is second nature.

🔍 Ask: Are we building 5S as a habit, not a project?

Tools That Support 5S

- ✅ Red Tags for sorting

- ✅ Shadow Boards for organizing tools

- ✅ Floor Marking Tape for layout clarity

- ✅ Visual SOPs and color-coded labels

- ✅ 5S Audit Checklists

These tools reinforce standardization and make deviations instantly visible — a key Lean principle.

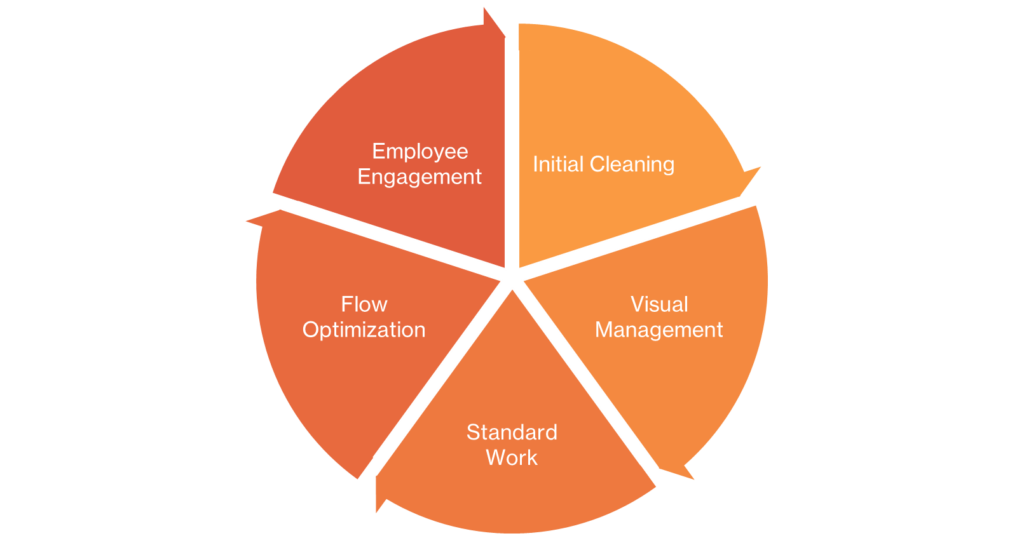

5S and the Lean Connection

| Lean Principle | How 5S Supports It |

|---|---|

| Waste Elimination | Removes unnecessary materials and movements |

| Visual Management | Makes the abnormal immediately visible |

| Standard Work | Creates consistency and efficiency |

| Flow Optimization | Reduces delays from disorganization |

| Employee Engagement | Involves everyone in workplace improvement |

Benefits of 5S Implementation

✅ Improved productivity and efficiency

✅ Safer work environment

✅ Reduced downtime from searching tools/materials

✅ Increased quality and fewer defects

✅ Greater employee ownership and morale

✅ Smoother audits and client visits

“When the workplace is in order, the mind follows.”

— A core Lean belief that 5S brings to life.

Real-World Example: The 5S Turnaround

At a mid-sized injection molding facility, implementing 5S led to:

- 37% reduction in tool changeover time

- 60% fewer workplace incidents

- Increased floor space by removing obsolete items

- Boosted team morale through clear ownership

The visual transformation alone impressed both auditors and customers — but the real impact was in sustained Lean behavior.

Common Challenges and How to Overcome Them

| Challenge | Solution |

|---|---|

| Initial excitement fades | Conduct regular audits and refresh training |

| Resistance from teams | Involve operators from day one, explain “why” |

| Lack of leadership support | Set clear expectations and lead by example |

| Inconsistent application | Use visual standards and 5S champions |

Conclusion: 5S is Not a One-Time Project — It’s a Culture

When done right, 5S becomes invisible — not because it’s gone, but because it’s embedded in how people think and act every day.

It’s the starting point of every Lean transformation and often the difference between temporary change and lasting impact.