Introduction: The Future of Industrial Automation

Artificial Intelligence (AI) and Machine Learning (ML) are at the heart of Industry 4.0, driving a new era of smart factories and intelligent manufacturing. From the United States to Japan and Germany, manufacturers worldwide are embracing AI-driven automation to enhance efficiency, reduce costs, and stay competitive. In fact, industries are investing heavily in AI – the global industrial automation market is projected to double by 2031, reaching over $400 billion – underscoring AI and ML’s pivotal role in the future of manufacturing.

According to a McKinsey & Company in blog Adopting AI at speed and scale: The 4IR push to stay competitive has given the futuristic revolution on Industry 4.0. AI adoption in manufacturing could unlock trillions of dollars in economic value, with AI helping to increase productivity and redefine business models in the sector. This is a clear signal that businesses worldwide are acknowledging the transformative power of these technologies. In this blog, we explore how AI and ML are revolutionizing industrial automation, with practical examples of their impact on efficiency, maintenance, quality, supply chains, and more. We also benchmark against leading industry trends to ensure you gain insights that meet global standards. Let’s delve into the keyways AI and ML are transforming modern industrial operations.

The Role of AI & ML in Modern Industrial Automation

AI and ML have emerged as transformative forces in industrial automation, enabling intelligent decision-making and data-driven process optimization. Unlike traditional automation (which follows pre-programmed rules), AI-powered systems learn from large datasets – identifying patterns, adjusting operations in real-time, and even predicting outcomes. This makes production lines far more agile and responsive.

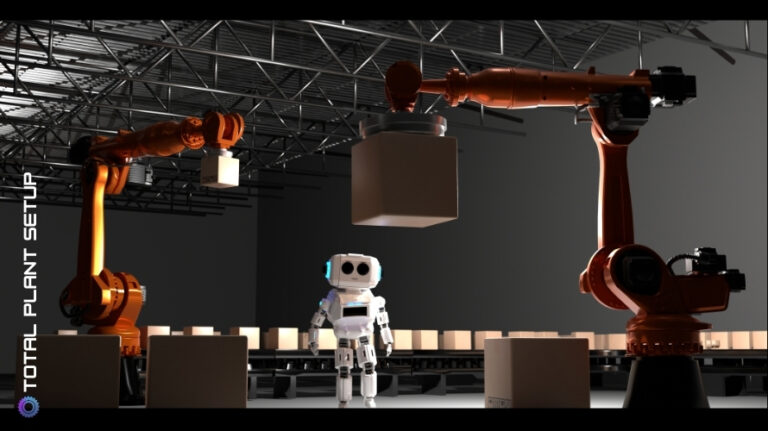

For example, AI algorithms can analyse sensor data to continuously tune equipment settings, achieving optimal performance without human intervention. These technologies represent a paradigm shift and are often described as the core of Industry 4.0. You can explore in depth how a Total Plant Setup is leveraging AI and robotics to transform industrial operations and empower factories to stay ahead in the cutting-edge global competition.

According to Boston Consulting Group (BCG), the integration of AI into industrial automation enables manufacturers to tap into deeper insights from their data, allowing them to optimize operations, enhance product quality, and predict future outcomes with greater accuracy. This combination of automation and AI is ushering in a new age of intelligent manufacturing, where businesses can achieve higher levels of performance than ever before. Learn more about BCG’s view on AI adoption in Industry 4.0 here.

Implementing AI in Automation

AI-driven solutions can boost manufacturing productivity by up to 20% and cut maintenance costs by 10%. This efficiency comes from AI’s ability to find inefficiencies that humans might overlook and adjust operations on the fly. Executives and engineering directors are prioritizing AI/ML adoption to maintain a competitive edge in a rapidly evolving market. Research highlights that companies that embrace AI and data-driven decision-making are seeing an increase in operational efficiency and are better positioned to drive innovation. Read more from Bain & Company’s report on AI’s role in manufacturing.

Enhancing Manufacturing Efficiency and Process Optimization

AI’s impact on operational efficiency is immediate. Machine learning models process real-time data from machines, IoT sensors, and production systems to streamline workflows. AI dynamically optimizes parameters like temperature, speed, and pressure based on historical and live data. This leads to peak throughput and quality without needing human intervention.

AI-powered systems dynamically adjust resources based on demand fluctuations. If a bottleneck occurs, AI can reroute tasks or adjust processes to minimize disruptions. These optimizations lead to faster cycle times and improved energy/material usage, resulting in sustainable practices.

According to a Harvard Business Article How AI Is Enabling Self-Learning Factories, narrates AI’s role in optimizing industrial processes extends far beyond merely automating tasks—it involves using advanced algorithms to continuously learn from data, enabling machines to adapt and improve autonomously. This results in not just greater efficiency but also a reduction in human error, enabling more consistent and sustainable production.

For more on how AI helps in optimizing operational processes, read this As per Bloomberg article More Than 4 Million Robots Are Working in Factories that discusses the future of AI in optimizing manufacturing efficiency.

Predictive Maintenance for Reduced Downtime

Unplanned downtime is a major challenge in manufacturing. AI and ML tackle this through predictive maintenance. By analysing sensor data (e.g., vibration, temperature, noise), AI detects early warning signs of wear and malfunction.

Instead of reactive maintenance, companies can schedule repairs based on predictive insights, cutting downtime by 30% to 50% and saving millions in lost productivity.

Research from the National Bureau of Economic Research (NBER) further confirms that predictive maintenance is revolutionizing industries by helping companies reduce unplanned downtime and improve asset reliability. Their findings show that businesses leveraging AI in maintenance practices see substantial improvements in uptime and overall productivity. Learn more from NBER on AI’s impact on industrial efficiency.

For example, an AI system might analyse the motor currents of a critical pump and notice a slight deviation from normal patterns. It could correlate this with past data indicating the pump is likely to fail in two weeks. Maintenance can then be scheduled at the next convenient window, avoiding an emergency shutdown. This proactive approach is not only cost-effective but is becoming a standard for modern industrial practices.

AI is making industrial robots more intelligent, flexible, and autonomous. In smart factories, robots can adapt to changing tasks and collaborate with humans safely. AI enables robots to learn optimal movements and adjust operating parameters over time, advancing from older, rigid systems.

For example, AI vision allows robots to identify parts on a conveyor and adjust their grip if parts are misaligned, enabling safer, more efficient production.

Autonomous guided vehicles (AGVs) and drones in warehouses are also leveraging AI to navigate and operate with minimal human input. These systems use AI to plan routes, avoid obstacles, and optimize their activity (like fetching parts or scanning inventory).

Conclusion: Embrace the Future of Manufacturing with AI

Industrial automation powered by AI and ML is no longer optional – it’s the new standard for manufacturing excellence. From predictive maintenance to AI-driven robotics, the benefits are undeniable. By integrating these technologies, manufacturers can achieve higher productivity, improved quality, and greater agility.

If you’re looking to harness AI and machine learning for industrial automation, contact us for a consultation. We provide tailored AI-driven solutions that help you stay ahead of the competition.

Together, let’s shape a smarter, more efficient future for manufacturing.