Introduction

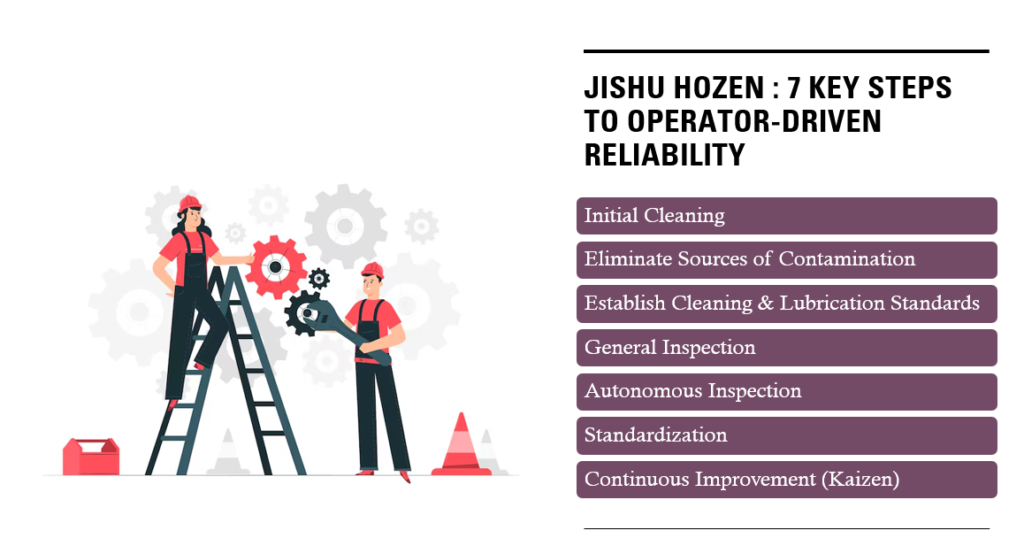

Jishu Hozen (自主保全), or Autonomous Maintenance, empowers frontline operators to perform basic maintenance tasks, ensuring machines are clean, safe, and ready — without waiting for maintenance teams. This Lean approach enhances ownership, reduces downtime, and is a critical pillar of Total Productive Maintenance (TPM).

What Is Jishu Hozen?

Jishu Hozen translates to “autonomous or self-maintenance.”

It empowers frontline operators to perform basic, routine maintenance activities such as:

- Cleaning

- Lubrication

- Inspection

- Tightening

This not only improves equipment reliability but also fosters a culture of ownership, pride, and accountability on the shop floor.

Why It Matters in Lean Manufacturing

In Lean environments, flow is everything — and machine stoppages can disrupt takt time, build-up waste, and kill momentum.

With Jishu Hozen, companies can:

- Reduce unplanned downtime

- Free up technical maintenance teams for complex tasks

- Keep machines in optimal working condition

- Improve operator engagement and process visibility

- Extend the lifecycle of equipment

Lean Principles Supported by Jishu Hozen

| Lean Principle | How Jishu Hozen Supports It |

|---|---|

| Jidoka (Built-in Quality) | Ensures abnormalities are detected early and corrected by operators |

| TPM | Forms one of the foundational pillars |

| Visual Management | Uses tags, labels, and standards to guide maintenance |

| Kaizen | Drives operator-led continuous improvement |

| Standardized Work | Promotes consistency in maintenance and inspection |

Real-World Example: From Reactive to Proactive

A mid-sized automotive supplier implemented Jishu Hozen across its welding line.

Before:

- Frequent stoppages due to loose fixtures and clogged nozzles

- Maintenance team stretched thin

- Operators had no visibility into root causes

After:

- Operators performed daily 10-minute checks and cleanings

- Early detection of loose parts and leaks

- 28% reduction in unplanned downtime in 3 months

- Maintenance team reallocated to preventive projects

Result: Improved OEE (Overall Equipment Effectiveness) and higher morale on the floor.

🛠️ Tools & Visual Aids for Jishu Hozen

- Red Tags for identifying abnormalities

- Daily Checklists for visual inspections

- Color-Coded Lubrication Maps

- Before/After Photos to track improvement

- Standard Work Sheets for daily maintenance tasks

Challenges and How to Overcome Them

| Challenge | Solution |

|---|---|

| Operator resistance | Educate on benefits and recognize their contributions |

| Lack of training | Offer visual, hands-on instruction using real equipment |

| Poor follow-through | Assign team leads and audits to ensure consistency |

| Time pressure | Integrate into shift startup routines (5–10 minutes max) |

Benefits of Jishu Hozen

- Faster response to machine issues

- Cost savings on emergency repairs

- Better OEE and throughput

- Cross-functional collaboration

- Culture of continuous improvement and accountability

Cultural Impact: Operators as Owners

More than just maintenance, Jishu Hozen shifts mindsets.

Operators go from “just running the machine” to owning the health, performance, and longevity of the equipment. This sense of pride enhances quality, teamwork, and Lean maturity.

Let’s walk through it step by step.

Understand the Purpose of Jishu Hozen

Before you begin, align your team with the why:

- Shift from reactive to proactive maintenance

- Empower operators to detect and prevent issues

- Free up technical teams for higher-value tasks

- Improve machine uptime and workplace ownership

Step 1: Initial Cleaning

Operators begin by thoroughly cleaning their equipment to:

- Remove accumulated dirt, oil, dust, and debris

- Reveal wear, loose parts, leaks, or abnormalities

- Create a baseline of cleanliness and machine condition

Tools used: Brushes, wipes, compressed air, red tags for abnormalities

Goal: Make issues visible and increase operator-machine familiarity

Step 2: Eliminate Sources of Contamination

Once the initial cleaning is done, the focus shifts to:

- Identifying why the machine gets dirty (leaks, design flaws, loose components)

- Modifying equipment to prevent future contamination

- Improving accessibility for cleaning and inspection

Kaizen thinking begins here — fix the root, not just symptoms.

Goal: Reduce cleaning workload and stabilize machine condition

Step 3: Establish Cleaning & Lubrication Standards

Now that contaminants are under control:

- Define what needs to be cleaned and lubricated

- Determine how, when, and by whom (usually the operator)

- Use visual controls: tags, color coding, labels, and charts

Tools: Lubrication maps, cleaning checklists, SOPs

Goal: Standardize daily care tasks to prevent machine wear and failures

Step 4: General Inspection

Operators are trained to inspect machine components beyond basic cleaning:

- Belts, bearings, bolts, hydraulic lines, sensors, etc.

- Learn how to detect early signs of wear, misalignment, vibration, or leaks

- Participate in equipment health checks with maintenance teams

Goal: Build operator capability and increase machine reliability

Step 5: Autonomous Inspection

With inspection skills built, operators now perform:

- Independent daily inspections as part of their routine

- Minor adjustments or fixes (tightening, topping fluids, etc.)

- Proactive communication with maintenance for bigger issues

Visual dashboards, tags, and logbooks help track findings.

Goal: Transition from passive operation to active ownership

Step 6: Standardization

Standardize everything learned in the previous steps:

- Visual SOPs for inspections, cleaning, and lubrication

- Clear schedules integrated into shift routines

- Defined roles between operators and maintenance staff

Use 5S principles and visual management to maintain discipline.

Goal: Create consistency across shifts and machines

Step 7: Continuous Improvement (Kaizen)

Finally, establish a system for ongoing improvement:

- Collect data on breakdowns, MTBF (Mean Time Between Failures), and downtime

- Encourage operators to suggest improvements

- Apply PDCA (Plan-Do-Check-Act) cycles to upgrade tasks and techniques

Involve cross-functional teams and recognize operator contributions.

Goal: Evolve beyond maintenance — toward process excellence

Conclusion: A Step Towards Lean Culture

Jishu Hozen isn’t just about wiping machines — it’s about building pride, visibility, and proactive care into your processes.

Train your people, give them the tools, and create a culture where maintenance is everyone’s responsibility.

💡 Start small. Stay consistent. Watch your shop floor transform.

Ready to make your operations Leaner, faster, and smarter? Start with these 21 foundational tools today!