Introduction:

In the pursuit of excellence, no improvement is too small.

That’s the philosophy behind Kaizen (改善) — a core pillar of Lean thinking and a powerful cultural mindset that fuels sustainable growth in every aspect of a business. Originating from Japan and embraced worldwide, Kaizen means “change for the better”. But its real strength lies in small, consistent, and people-driven improvements that compound over time.

Let’s dive deep into the essence, methodology, and impact of Kaizen — and how you can apply it in your workplace.

What is Kaizen?

Kaizen (改善) combines two Japanese words:

- Kai (改) – Change

- Zen (善) – Good or for the better

Together, it represents a philosophy of continuous improvement through incremental changes rather than dramatic overhauls.

Kaizen isn’t just a tool — it’s a mindset and culture that empowers employees at every level to identify problems, suggest solutions, and take action.

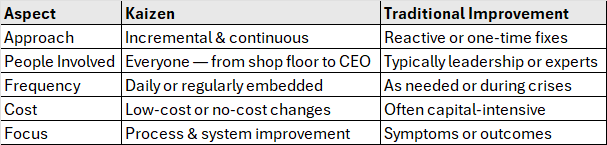

Kaizen vs. Traditional Problem-Solving

Types of Kaizen in Practice

- Daily Kaizen : Small process improvements suggested and implemented by employees during regular work.

- Kaizen Events (or Blitz) Short-term, focused workshops (1–5 days) where cross-functional teams tackle a specific problem or area.

- Kaizen Circles: Small groups of employees that meet regularly to identify improvement opportunities and execute changes together.

Kaizen Implementation: 6-Step Method

Here’s a practical step-by-step flow for executing a Kaizen improvement:

- Identify the Problem or Opportunity Use data, observation, or feedback to find improvement areas.

- Analyze the Current Process : Use tools like VSM, 5 Whys, or Fishbone Diagrams.

- Generate Improvement Ideas: Brainstorm low-cost, simple ideas with frontline teams.

- Implement the Change: Test the solution in a controlled way (e.g., pilot area or trial run).

- Measure Results : Track metrics like lead time, cycle time, waste reduction, or defect rate.

- Standardize and Repeat: If successful, document and standardize the new method. Then move to the next improvement.

Kaizen and Lean Principles

Kaizen directly supports several Lean manufacturing principles:

| Lean Principle | Kaizen Alignment |

|---|---|

| Waste Elimination | Encourages everyone to find and reduce Muda |

| Respect for People | Empowers workers to drive improvement |

| Continuous Flow | Improves flow through small process tweaks |

| Visual Management | Makes improvements visible and measurable |

| Standardized Work | Builds consistent processes after changes |

Benefits of Kaizen

- Boosts employee morale and engagement

- Reduces waste and operational costs

- Improves quality and consistency

- Fosters a culture of collaboration

- Encourages innovation from the bottom up

- Accelerates Lean transformation

- Increases responsiveness to market/customer needs

Real-World Example: Kaizen in Action

At a precision machining company, operators noticed that switching tool bits took 3–5 minutes per part.

Using a Kaizen approach, they:

- Suggested a nearby tool holder and magnetic tray

- Reduced search time and hand movement

- Standardized the layout for every workstation

Result? Tool changeover time dropped to under 60 seconds — and was replicated across 14 machines.

Cost? Less than $50 per station.

Impact? Massive — both in time savings and operator confidence.

Common Kaizen Challenges and How to Overcome Them

| Challenge | Solution |

|---|---|

| Resistance to change | Celebrate small wins and involve teams |

| No time for improvement | Integrate Kaizen into daily routines |

| Poor follow-through | Assign ownership and track results |

| Lack of ideas | Provide examples and run Kaizen events |

| No leadership buy-in | Show ROI with simple pilot improvements |

Kaizen Tools That Support Execution

- 5 Whys

- PDCA Cycle (Plan-Do-Check-Act)

- Value Stream Mapping

- Fishbone (Ishikawa) Diagram

- Pareto Analysis

- A3 Problem Solving Sheets

- Standard Work Combination Sheets

Conclusion: Kaizen is a Culture, Not a Project

Kaizen is not about perfection — it’s about progress, made daily.

When everyone from operators to leaders is encouraged to think critically, act boldly, and continuously improve, real transformation begins.

You don’t need a massive budget.

You need mindset, discipline, and belief in people.

💡 Start with small steps. Repeat daily. Let Kaizen drive your excellence.