Introduction

In today’s fast-paced, ever-changing global economy, demand volatility has become a defining characteristic of the manufacturing landscape. Technological advancements, shorter product life cycles, and increasing consumer demand for customization mean manufacturers must constantly adapt. Traditional methods, designed for stable, repetitive production, often fail to cope with these fluctuations. Enter Shojinka — a powerful Japanese concept that enables flexible, resilient production lines through a dynamic workforce.

What is Shojinka?

Derived from Japanese, Shojinka means “flexible manpower” or “production levelling by manpower.” It refers to the practice of continually adjusting the number of workers and their task assignments to match the fluctuating demands of production. Unlike rigid, fixed-line operations, Shojinka empowers teams to quickly reconfigure, ensuring high productivity and quality without over-reliance on specialized individuals.

Where is Shojinka Used?

Shojinka is predominantly used in industries where demand unpredictability is high — such as automotive, electronics, and consumer goods manufacturing. Companies like Toyota, Honda, and other lean practitioners have famously adopted Shojinka principles to build resilient, high-performing production environments that flex with customer needs.

Why Shojinka Matters?

- Manages demand fluctuations effectively

- Reduces downtime and waste

- Enhances employee skills and morale

- Mitigates risks from workforce turnover

- Enables efficient use of resources and space

Step-by-Step Procedure to Implement Shojinka

Step 1: Skill Mapping

Skill mapping is the first crucial step toward building a flexible workforce. Begin by assessing the current skill sets of each employee, creating a comprehensive inventory of competencies available within the team. Identify any skill gaps that could hinder production flexibility and prioritize training needs accordingly. Understanding where your workforce currently stands helps in planning targeted development efforts and ensures that no task or process is overly dependent on a single individual. A visual skill matrix is often useful in this step to provide clarity and easy updates as team members gain new competencies. Introduction to Skills Matrix.

Step 2: Develop Training Plans

After skill mapping, the next focus is on developing customized training plans for each employee. These plans should address the identified skill gaps and encourage multi-skilling and cross-functional expertise. Structured and ongoing training ensures employees can perform multiple roles within the production process, improving the adaptability of the workforce. Training should be hands-on, task-specific, and aligned with production needs. Encouraging a culture where continuous learning is valued will empower operators to embrace new challenges and drive overall production efficiency.

Step 3: Standardize Work Methods

Standardization is vital for consistency, quality, and training efficiency. Develop clear, simple, and visual work instructions for every critical task on the shop floor. These instructions should be easy to understand and follow, even for those new to a role. By standardizing work methods, variability in task execution is reduced, making it easier for operators to shift between roles without sacrificing productivity or product quality. Benefits of Standard Work.

Step 4: Design Flexible Layouts

Physical layouts must support workforce flexibility. Implement U-shaped or modular layouts that minimize operator movement, enhance communication, and enable one operator to manage multiple tasks when needed. A well-designed layout simplifies material flow, reduces waste, and ensures that employees can easily adjust to changes in product mix or production volumes. Modular layouts also allow quick reconfiguration without major disruptions. Explore Lean Facility Layouts.

Step 5: Foster a Culture of Rotation and Learning

Flexibility isn’t achieved through systems alone — it requires a cultural shift. Foster an environment where job rotation is normal and encouraged. Regularly rotating employees through different tasks enhances their skills, reduces monotony, and prevents the over-specialization of workers. Recognition programs that reward skill diversification and adaptability help build motivation. Additionally, a culture of learning ensures that employees see skill acquisition as a career growth opportunity rather than a burden, leading to higher engagement and retention rates.

Step 6: Introduce Low-Cost Automation

Low-cost automation plays a supportive role in Shojinka by simplifying tasks and improving ergonomics. Introducing basic automation tools, such as gravity rollers, automatic counters, or simple jigs, reduces the physical strain on workers and makes tasks easier to learn and perform. The goal is not to replace human workers but to enhance their efficiency and make flexible operations smoother. Low-Cost Automation Insights.

Step 7: Align Logistics with Flexibility

A flexible production system demands equally flexible logistics operations. Inbound and outbound materials must flow seamlessly to support rapid changes in production needs. Logistics planning should aim to minimize excess inventory while ensuring timely supply to workstations. Designing materials handling routes that can adjust with the production layout reduces bottlenecks and supports smoother transitions during shifts in product mix or volume. Flexible logistics are critical for ensuring that operational agility extends beyond the production line to the entire supply chain ecosystem.

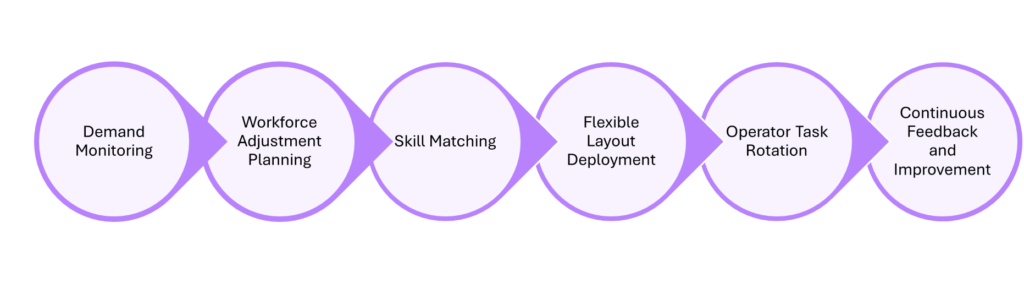

Shojinka Process Flow

- Monitor demand regularly for shifts.

- Plan workforce adjustments based on demand volume and product mix.

- Match tasks to available, trained personnel.

- Reconfigure layouts as needed to optimize production flow.

- Rotate workers to maintain multi-skill proficiency.

- Gather feedback to continuously refine flexibility and efficiency.

The Shojinka Formula: Adjusting Workforce Based on Demand

Shojinka also involves a simple but powerful calculation to adjust the number of operators based on production needs.

Basic Shojinka Formula:

Number of Operators needed = Total line cycle time / Takt time

Where:

Total Line Cycle Time = Sum of all work content time needed to complete one unit (in seconds or minutes).

Takt Time = Available production time \ Customer demand (units).

Example:

Available time per shift: 8 hours = 28,800 seconds

Customer demand per shift: 600 units

Thus,

Takt time = 28,800 / 600 = 48 seconds per unit

If your total line work content = 240 seconds, then

Number of operators = 240 / 48 = 5 Operators

Thus, you would ideally deploy 5 flexible operators to meet that day’s production demand.

As demand fluctuates:

Lower demand (e.g., 400 units) = fewer operators needed.

Higher demand (e.g., 800 units) = more operators deployed.

This dynamic adjustment ensures efficiency and keeps productivity aligned with market needs.

How to Promote Worker Flexibility,

Building a truly flexible team starts with culture. Organizations must:

- Motivate employees through structured learning and career growth.

- Develop simple standards to ensure easy task comprehension.

- Reduce repetitive strain and boredom through job rotation.

- Encourage open communication and collaboration across teams.

When employees feel valued and challenged, their resistance to change diminishes — making flexibility a shared goal rather than a management-imposed requirement.

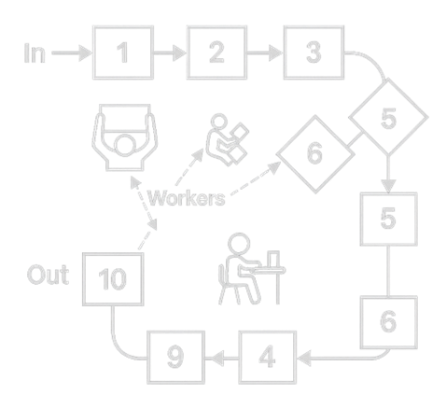

Designing Flexible Layouts

1. “U”-Shaped Layouts for Enhanced Teamwork and Material Flow

A U-shaped layout strategically places workstations around a curved path, allowing operators to handle multiple processes within a small footprint. This design minimizes unnecessary walking, reduces cycle times, and promotes active communication among team members. Operators can easily assist each other during production peaks, maintaining continuous flow and minimizing downtime. Additionally, materials can be introduced and completed products can exit from the same side of the U, simplifying inbound and outbound logistics. By creating a natural flow of information and materials, U-shaped layouts significantly improve production agility, line balancing, and teamwork on the shop floor.

2. Modular Workstations for Rapid Reconfiguration

Modular workstations are designed to be flexible and easily adjustable based on the shifting needs of production. Whether responding to a new product launch, seasonal volume increases, or custom order requirements, modular setups allow manufacturers to rearrange or resize work areas without heavy investment or long downtimes. Each module can function independently or as part of a larger cell, offering companies the ability to experiment with layouts and quickly implement continuous improvement initiatives. This adaptability not only maximizes the utilization of space but also empowers a flexible workforce to stay aligned with production goals as demand evolves.

3. Flexible Logistics to Support Dynamic Production Needs

Having flexible logistics systems is essential for fully realizing the benefits of a flexible manufacturing environment. This means aligning storage, supply chain, and material transport systems with the adaptable nature of production layouts. Instead of rigid, fixed material handling routes, flexible logistics enable just-in-time delivery of components, minimize excess inventory near workstations, and prevent bottlenecks. Mobile racks, dynamic inventory zones, and agile material flow strategies ensure that production cells receive the right parts at the right time, even as product mixes or volumes shift. A synchronized logistics system not only reduces waste and storage costs but also ensures uninterrupted production flow, contributing directly to operational excellence.

A flexible layout minimizes waste, reduces walking distance, and increases communication between operators — all essential in a Shojinka environment.

Benefits of Shojinka Implementation

- Higher Agility: Quickly adapt to changes in order volumes and product types.

- Cost Savings: Lower infrastructure and training costs compared to highly specialized setups.

- Increased Productivity: Reduced downtime through smoother transitions between tasks and shifts.

- Better Workforce Morale: More engaging work leads to higher retention and performance.

- Enhanced Quality: Standardization and cross-skilling improve consistency.

Conclusion

Shojinka isn’t just a technique — it’s a philosophy of agility, respect for people, and operational excellence. By building flexible teams and adaptable infrastructures, manufacturers can achieve high efficiency and outstanding service levels even amid unpredictable market conditions. Organizations that master Shojinka today will be the ones thriving in the volatile markets of tomorrow.

Ready to build a more flexible, future-ready production system? Start with Shojinka.